What are the Best Practices for PCB Prototype Assembly?

Printed Circuit Boards (PCBs) are the pulse of present day electronics, whether in smart phones, medical devices, or mechanical gear. Some time recently a item hits full-scale generation, it frequently goes through a few rounds of prototype assembly. PCB prototype assembly is the basic stage where thoughts meet reality, and indeed minor slips can lead to costly delays or item failures.

To ensure success, embracing best practices amid prototype assembly is vital. Let’s jump profound into the key steps and tips that can make or break your PCB project.

1.Start with a Clear and Nitty gritty Design

Every fruitful PCB prototype begins with a strong Design. Clear schematics, well-organized component libraries, and coherent board formats are basic. Architects must utilize up-to-date Electrical Computer-Aided Design (ECAD) devices such as Altium Originator, KiCAD, or Eagle.

Key points:

- Double-check the schematic for mistakes some time recently moving to the layout.

- Keep your Design straightforward; prioritize clarity over compactness in prototypes.

- Use legitimate Design for manufacturability (DFM) rules to maintain a strategic distance from issues later.

- Include test focuses and investigating highlights on the board.

Tip: Run a Design Rule Check (DRC) some time recently finalizing the Design to capture dividing, clearance, or layer issues early.

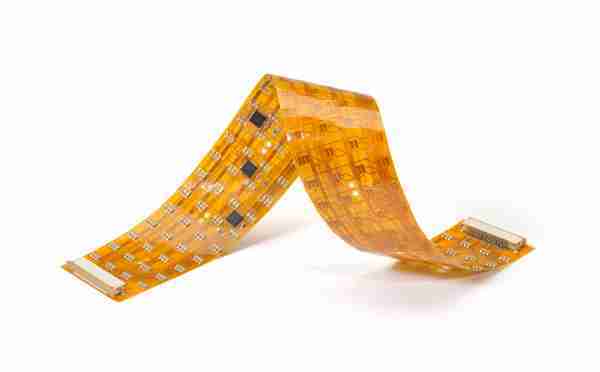

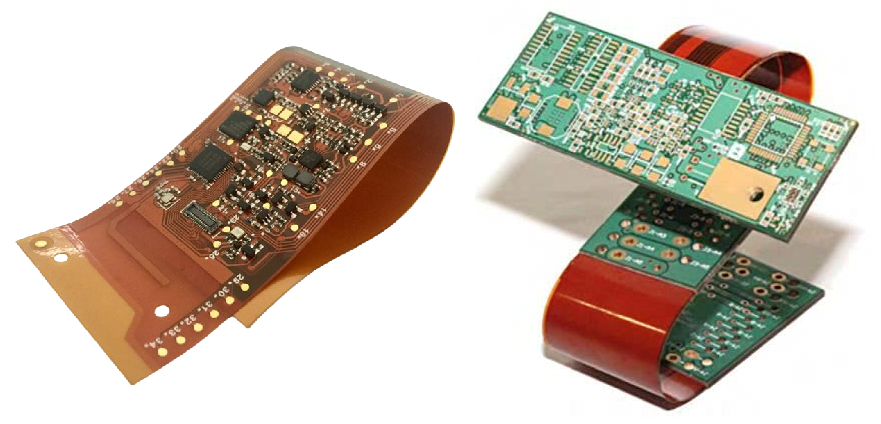

2.Select the Right PCB Materials

The choice of fabric influences your prototype’s strength, fetched, and execution. For most standard applications, FR4 fabric is a solid and cost-effective choice. In any case, for high-frequency or high-speed circuits, you might require specialized substrates like Rogers laminates.

Best hones for fabric selection:

- Evaluate warm, mechanical, and electrical properties based on your application.

- Consult with your constructing agent to guarantee fabric compatibility with their processes.

- Factor in costs: Prototype Boards may require diverse fabric methodologies than last production.

Tip: If you’re uncertain, begin with standard FR4 for your early prototypes to diminish costs.

3.Collaborate Closely with Your PCB Producer and Assembler

Open communication with your fabricating and assembly accomplices can anticipate numerous issues. Experienced accomplices frequently spot potential Design blemishes and suggest improvements.

Steps to follow:

- Share Gerber records, Charge of Materials (BOM), pick-and-place records, and assembly drawings in standardized formats.

- Ask for a Design for Assembly (DFA) audit some time recently production.

- Understand the capabilities and restrictions of your constructing agent, particularly for progressed innovations like microvias or fine-pitch components.

Tip: Set up a input circle. The assembler’s bits of knowledge can altogether progress the Design in consequent prototype iterations.

4.Optimize the Bill of Materials(BOM)

A clean, clear, and well-optimized BOM spares time and dodges disarray amid assembly. Make beyond any doubt your BOM includes:

- Correct portion numbers (producer and provider codes).

- Clear component descriptions.

- Quantity and designators coordinating the PCB layout.

- Alternative portion proposals for basic components.

Tip: Utilize common, promptly accessible components to speed up obtainment, particularly in the prototype stage when sourcing delays can affect timelines.

5.Component Arrangement and Orientation

Proper component arrangement and introduction are vital for useful and manufacturable PCBs. Components ought to be situated consistently to guarantee productive flag stream and less demanding debugging.

Placement best practices:

- Place high-speed or touchy components near to connectors or basic paths.

- Keep polarized components (e.g., diodes, electrolytic capacitors) clearly stamped and situated uniformly.

- Avoid setting components as well near to PCB edges unless completely necessary.

Tip: Gather comparable components together where possible—it makes a difference in robotized arrangement and manual inspection.

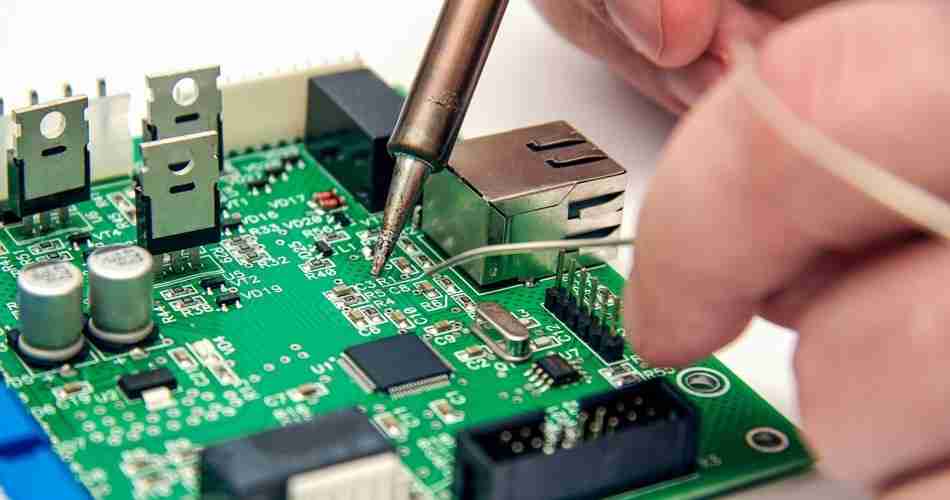

6.Pay Consideration to Fastening Techniques

In PCB prototype assembly, destitute patching is a common cause of useful disappointments. Whether you’re utilizing manual patching for a few Boards or a reflow broiler for group prototypes, exact patching hones must be followed.

Soldering recommendations:

- Use the adjust patch glue sort and stencil thickness for the components.

- Maintain reliable temperature profiles amid reflow to anticipate absconds like tombstoning or cold joints.

- For hand fastening, guarantee administrators are IPC-certified or well-trained.

Tip: For fine-pitch components like QFNs or BGAs, dodge manual fastening if conceivable. Utilize reflow patching with proficient gear for best results.

7.Careful Review and Testing

Prototype PCBs must be reviewed completely after assembly. This step catches surrenders early some time recently they cascade into greater issues amid useful testing.

Inspection techniques:

- Visual Assessment: Manual checking beneath magnification.

- AOI (Automated Optical Inspection): Machines filter for arrangement, lost components, patch bridges, etc.

- X-ray Review: Fundamental for covered up joints like those beneath BGAs.

Tip: Indeed if you utilize AOI, a last manual assessment is astute for catching irregularities that machines might miss.

8.Include Test Points for Debugging

During prototyping, it’s not about just making the board work once—it’s about understanding why it works (or doesn’t). Test points are critical.

How to implement:

- Provide accessible test points for key nets like power, ground, clocks, and critical signals.

- Use test pads or small vias designed specifically for oscilloscope probes.

- Label test points clearly to speed up troubleshooting.

Tip: Allocate space for a debug connector (like a JTAG or UART header) if your circuit includes programmable devices.

9.Validate the Prototype Thoroughly

Once the board powers up successfully, deeper validation is needed. Check not only if the board works but if it performs within specifications.

Validation checklist:

- Measure power rails for correct voltages.

- Verify signal integrity for high-speed lines.

- Test thermal performance under load conditions.

- Validate software integration if the PCB interfaces with firmware.

Tip: Document all findings meticulously—it’ll make redesigns and iterations much easier.

10.Prepare for Iterations

Rarely does the first prototype get everything right. Expect a few iterations.

Best practices for iteration:

- Record all design changes based on prototype feedback.

- Implement Engineering Change Orders (ECOs) methodically.

- Keep track of revision numbers clearly in all files (Gerbers, BOMs, layouts).

Tip: Start with a small batch of prototypes before scaling up production based on validated designs.

11.Consider Using Turnkey PCB Assembly Services

For startups, small teams, or solo engineers, turnkey PCB assembly services can simplify the process greatly. These services handle sourcing, assembly, and basic testing.

Why consider turnkey services:

- Speed: Faster time to functional boards.

- Quality: Professional handling reduces assembly errors.

- Convenience: One-stop-shop from order to delivery.

Tip: Ensure your turnkey partner can handle the complexity of your design—especially if it involves fine-pitch components or advanced PCB technologies.

Conclusion

PCB prototype assembly is much more than fair putting components on a board. It’s a carefully coordinated prepare including Design perseverance, fabric determination, collaboration, exactness fastening, and thorough testing. Each choice made amid this stage impacts the victory of the last product.

By taking after these best hones, you can decrease chance, spare time and cash, and quicken the travel from thought to reality. A prototype is not fair a test board—it’s a establishment stone for the product’s future.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu